The Best 3D Printer Models of 2025

3D printer tech has really taken off recently. It started small but now everyone’s using it. Before, you needed pricey gear and serious skills. Today, hobbyists, students, and pros all use it. Now you’ll find all kinds – cheap starter models right up to machines making pro-level stuff.

So many choices! Picking a 3D printer can seem tough. You might be printing prototype designs, custom home things, art models, or parts for work. A perfect machine exists for your job. Our detailed look shows top models for 2025. We cover their features, what they do well, where they fall short, and best uses. This helps you decide wisely.

Creality Ender 3 V3 SE: High-Performance 3D Printing at Its Best

The Creality Ender 3 V3 SE stands out as the best beginner 3D printer that doesn’t compromise on quality or performance. This FFF/FDM printer features a generous build area of 220 x 220 x 250 mm and can achieve layer resolutions between 100-350 microns, making it versatile enough for most common printing needs.

What makes this model shine is its exceptional value proposition. Despite its affordable price tag, it offers features typically found in more expensive printers, like auto bed leveling and a robust metal frame. The machine’s straightforward assembly process gets you printing within 30 minutes of unboxing.

Pros:

- Excellent print quality for the price

- Reliable performance with minimal maintenance

- Easy setup and user-friendly operation

- Strong community support and readily available upgrades

Cons:

- No touchscreen interface

- Lacks a filament run-out sensor

- No built-in camera for remote monitoring

Anycubic Kobra S1: Versatile and User-Friendly 3D Printer

The Anycubic Kobra S1 delivers precision and reliability in a well-designed package. With its 250×250×250 mm build volume and CoreXY structure, this printer offers both speed and accuracy. The fully enclosed design makes it perfect for printing with materials that require consistent temperatures.

What truly sets the Kobra S1 apart is its outstanding accuracy. In rigorous testing, it achieved perfect scores in dimensional precision, bridging, and overhangs. The printer’s intuitive interface makes it accessible for newcomers while offering enough advanced features to satisfy experienced users. This is the printer you want if accuracy is your top priority.

Pros:

- Exceptional print accuracy

- Fast printing speeds

- Multifilament capability

- Fully enclosed design for temperature stability

Cons:

- Limited access to internal components

- Slightly smaller build volume than some competitors

- Higher price point than entry-level models

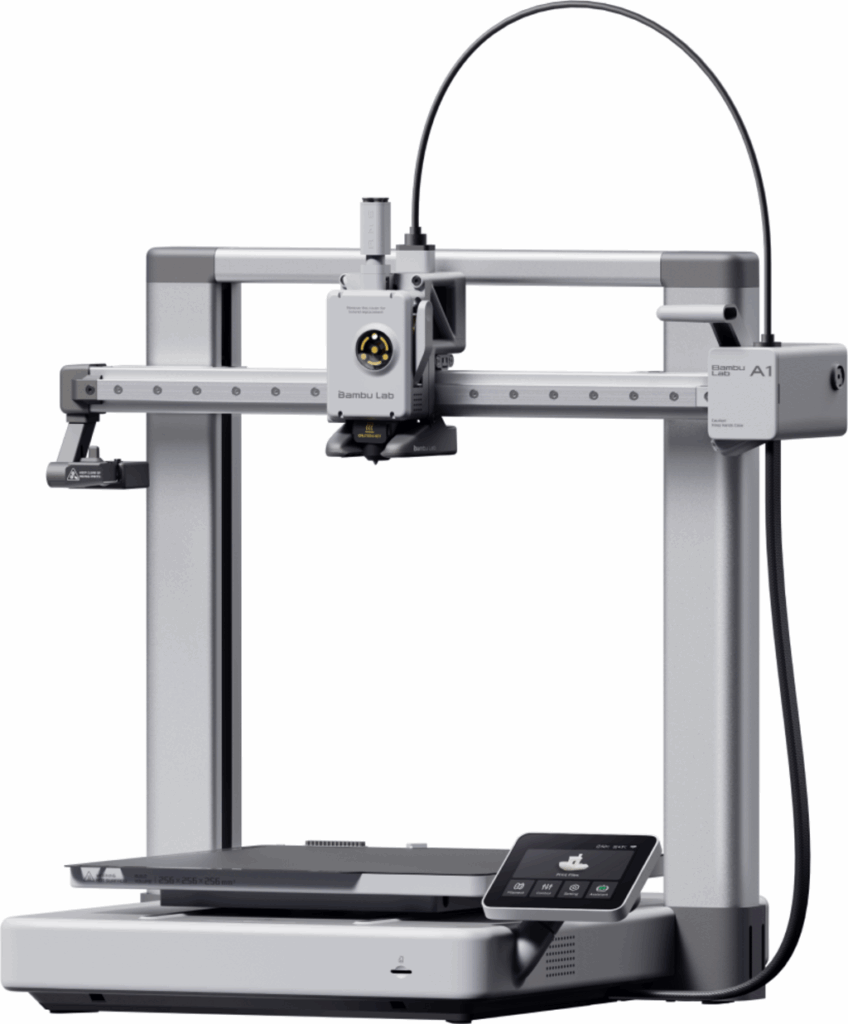

Bambu Lab A1: Cutting-Edge Technology for Exceptional Prints

The Bambu Lab A1 has quickly earned a reputation as the best 3D printer on the market for its combination of speed, quality, and versatility. With a build volume of 256 x 256 x 256 mm and layer resolution ranging from 80-280 microns, this printer delivers professional-quality results at impressive speeds.

What makes the A1 truly special is its AMS Lite (Automatic Material System), which enables up to 4 colors to be used in a single print. The printer features a tool head acceleration of 10,000 mm/s and pressure advanced technology for exceptional detail. For anyone looking to create multicolor models without the hassle of manual filament changes, this printer is a game-changer.

Pros:

- Ultra-fast printing capabilities

- Multi-filament versatility with the AMS Lite system

- Exceptional build quality and reliability

- User-friendly setup and operation

Cons:

- More complex software than some competitors

- No enclosure (though this allows for easier access)

- Heated platform limited to 80°C

FormLabs Form 4: Professional-Grade Resin 3D Printing Solution

The FormLabs Form 4 represents the pinnacle of desktop resin 3D printing technology. Using Masked Stereolithography (MSLA) with a Low Force Display print engine, this printer achieves extraordinary detail with layer resolutions between 25-300 microns in a 145 × 145 × 185 mm build area.

What distinguishes the Form 4 is its ability to produce prints that rival injection-molded parts in quality and finish. The improved auto-fill feature and redesigned resin tanks make operation cleaner and more efficient than previous generations. While this is the most expensive printer on our list, professionals who need production-quality parts will find the investment worthwhile.

Pros:

- Incredibly detailed prints with smooth surfaces

- Wide range of specialized materials available

- Improved auto-fill system reduces mess

- Excellent for small production runs

Cons:

- Premium price point

- Resin materials are expensive

- Requires additional wash and cure equipment

Original Prusa MK4S: Precision and Reliability in 3D Printing

The Original Prusa MK4S takes what people love about Prusa and makes it better. It has a build space of 250 x 210 x 220 mm. Layer detail ranges from 50 to 300 microns. This FDM machine makes steady, good prints.

Its big strengths are working reliably and efficiently. That makes it a great pick for a 3D printing business needing steady output. Automatic bed leveling and first-layer checks mean prints stick well every time. Low maintenance needs equal less fuss between jobs. It balances pro features with easy use well.

Pros:

- Exceptional reliability for continuous printing

- Versatile material compatibility

- Easy to use with minimal maintenance

- Strong community and manufacturer support

Cons:

- Higher price point than entry-level models

- Single extruder limits multicolor printing

Bambu Lab X1 Carbon: Premium Features for Advanced 3D Printing

The Bambu Lab X1 Carbon builds on what works well in the A1, adding high-end upgrades. This closed printer gives you 256 x 256 x 256 mm space. Set layers from 50 to 400 microns. Good for testing ideas or making things regularly.

As a multicolor 3D printer, it shines with its AMS system. This holds and switches up to 4 materials. The sealed body lets you use hotter plastics safely. It keeps up good speed and accuracy. Product designers needing quick models in various materials or colors will find it handles multiple jobs well.

Pros:

- Easy multifilament printing capability

- Exceptional print speed without sacrificing quality

- Enclosed design for printing specialty materials

- Outstanding build quality and reliability

Cons:

- Generates waste filament during color changes

- Higher price point than many competitors

- Complex software may have a learning curve

Elegoo Saturn 3 Ultra: High-Detail Resin Printing with Speed

The Elegoo Saturn 3 Ultra brings big resin printing within reach. It packs a sharp 12K screen into a large build area. This gets you fine details, ideal for miniatures, jewelry, or dental pieces.

Speed plus detail makes this model stand out. Its mono LCD gets layers done quicker than older resin machines. That means shorter print times. For hobbyists or pros wanting high-detail work affordably, it hits a sweet spot.

Pros:

- Outstanding detail with 12K resolution

- Large build volume for a resin printer

- Fast printing speeds with monochrome LCD

- Excellent value for the capabilities

Cons:

- Requires careful handling of resin materials

- Post-processing is more involved than FDM printing

- Ventilation needed due to resin odors

Creality Halot-Mage S 14K: Ultra-High Resolution 3D Printing

The Creality Halot-Mage S 14K stands as the best 3D printer for miniatures on the market, offering unprecedented resolution for incredibly detailed prints. With a build area of 218 x 123 x 230 mm and layer resolutions from 0.02-0.09 mm, this resin printer delivers astonishing levels of detail for miniatures and small models.

The printer’s 14K resolution is its standout feature, producing models with virtually invisible layer lines and capturing the finest details in your designs. The flip-top lid design and quick-release build platform make the typically messy resin printing process more manageable. For hobbyists creating gaming miniatures or jewelers producing detailed prototypes, this printer sets a new standard for detail.

Pros:

- Incredible 14K resolution for extremely detailed prints

- Solid build quality and reliability

- Simplified resin tank design for easier maintenance

- Reasonable build volume for a high-resolution printer

Cons:

- No auto-fill resin system

- Still requires thorough cleaning and maintenance

- More expensive than entry-level resin printers

Original Prusa XL: Large-Scale 3D Printing for Professionals

The Original Prusa XL stands as the definitive best large 3D printer for professional applications, offering an impressive 360 x 360 x 360 mm build volume. This COREXY machine takes advantage of Prusa’s latest innovations, including a revolutionary multi-tool changer head for efficient multifilament printing.

What truly distinguishes the XL is its modular design that can adapt to changing needs—from a single filament setup to a sophisticated multi-material configuration with up to five tool heads. Rather than loading and unloading filaments during printing, the printer automatically switches between complete tool heads, dramatically reducing print times for multi-material projects. For engineering and professional applications requiring large parts with multiple materials, the XL is unmatched.

Pros:

- Large build volume for substantial projects

- Revolutionary tool-changing system for multiple materials

- Modular design that grows with your needs

- Professional-grade print quality and reliability

Cons:

- Significant initial investment

- Considerable space requirements

- Time-consuming setup process

- No enclosure in the standard configuration

Creality K1C: Fast and Reliable 3D Printing for Every Project

The Creality K1C represents the ideal balance of speed, reliability, and enclosed design at a mid-range price point. With a build area of 220 x 220 x 250 mm and layer resolutions from 10-350 microns, this printer delivers exceptional results across a wide range of materials.

The K1C’s fully enclosed design makes it ideal for educational environments, keeping fingers away from moving parts and containing any fumes. Its top speed 3D performance is complemented by a direct drive clog-free extruder and unicorn tri-metal nozzle that can handle abrasive materials with ease. The integrated AI camera provides real-time monitoring and failure detection, making this an exceptionally reliable printer for continuous use.

Pros:

- High-quality, robust construction

- Fast print speeds without sacrificing quality

- Fully enclosed design for safety and temperature control

- AI camera for print monitoring and failure detection

Cons:

- Print quality can be affected at maximum speeds

- No multifilament support without upgrades

- Heavier than many competitors

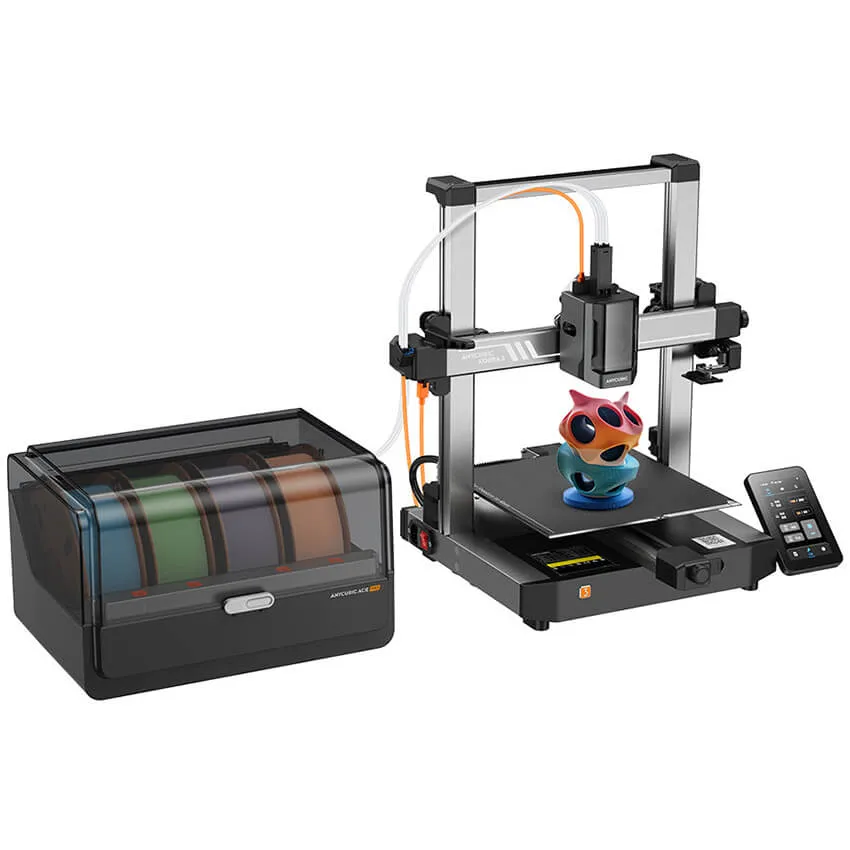

Anycubic Kobra 3 Combo: All-in-One Solution for 3D Printing Enthusiasts

The Anycubic Kobra 3 Combo lets you start multi-material printing affordably. Its build space is 220 x 220 x 250 mm. You can set layer detail from 50 to 300 microns. This gets good prints, whether you’re new or experienced.

What stands out is the included Anycubic Ace Pro box. It handles up to 4 different materials at once. A solid metal frame keeps things steady for cleaner prints. A big touchscreen makes controlling it simple. If you want multi-color output without paying top dollar, this machine does it well without high cost.

Pros:

- Affordable multifilament printing capability

- Fast single-filament print speeds

- Easy setup and operation

- Large, intuitive touchscreen interface

Cons:

- No excess filament tray

- Slower speeds when using multiple filaments

- Open frame design limits some material options

FAQs

What Exactly is a 3D Printer?

3D printers make solid objects. They build them up, layer by layer, starting from a digital plan. It’s different from older methods that carve things out of big blocks. This approach adds material only where necessary. That means it uses only what’s necessary, creating less waste. Common desktop types melt plastic thread (FDM/FFF) and lay it down carefully. Others use liquid resin (SLA/MSLA/DLP) where light makes it solid.

Learning How to use a 3D printer is easier now than before. Newer machines handle tricky stuff themselves. They adjust automatically and have simpler menus. Good prep software helps too. Main steps stay simple: make or find a model, get it ready for printing, then send it to your machine. Many printers connect wirelessly. You can often print from your phone. This makes the whole thing much more straightforward.

What Materials Can Be Used in 3D Printing?

The range of materials available for 3D printing has expanded dramatically, enabling the creation of more useful 3D prints for various applications. FDM printers typically use plastic filaments such as:

- PLA (Polylactic Acid): A biodegradable plastic ideal for beginners

- ABS (Acrylonitrile Butadiene Styrene): Durable and heat-resistant

- PETG: Combines strength with flexibility and food safety

- TPU: Flexible rubber-like material

- Nylon: Strong and durable with excellent wear resistance

- Carbon fiber-infused filaments: For added strength and rigidity

- Wood-filled filaments: For a natural wood-like appearance

- Metal-filled filaments: For metallic appearance and weight

Resin printers use photopolymer resins that come in various formulations:

- Standard resins for general purposes

- Engineering resins for functional parts

- Dental resins for medical applications

- Castable resins for jewelry making

- Flexible resins for elastic parts

Want pro-level prints? Plan on $1,000 to $5,000 for machines giving pro-level results in work settings. The fastest 3D printer models often cost extra. They need special parts and design. But for making things regularly, saving time matters.

Starting with a cheap 3D printer is a smart move for newcomers. It lets you dip toes in without spending lots. Many budget models now pack features once found only on pricier ones. Think auto-leveling beds and filament detectors.